INTRODUCING THE SECTION C.B.N.

INTRODUCING THE ELEMENT SECTION C.B.N.

Element's most environmentally responsible board to date. Discover the journey we took to realize this project and what it holds for the future.

If not now, when?

The Factory

Looking out across the Oiartzun valley in the Spanish Basque Country, sat at a picnic table across from Jean-Marie Desloques, a long time employee and one of the main guys behind the HLC skateboard factory, the hum of its machines make the building buzz in the background. Jean-Marie stretches his hand out pointing at the HLC factory complex that also comprises their office HQ and distribution center. With a nostalic vibe, he tells us how it all started. "We've been doing this since 2000, but we've been making really good boards since 2002."

HLC is a family business, founded by the Iraola brothers who grew up in the local area. From a young age, they were exposed to manufacturing through their family's furniture business. When the time came, their family know-how and passion for skateboarding took over and they started making their own boards. Since then, HLC has grown from making decks in a small garage to running a state-of-the-art factory, manufacturing skateboards to the highest standards.

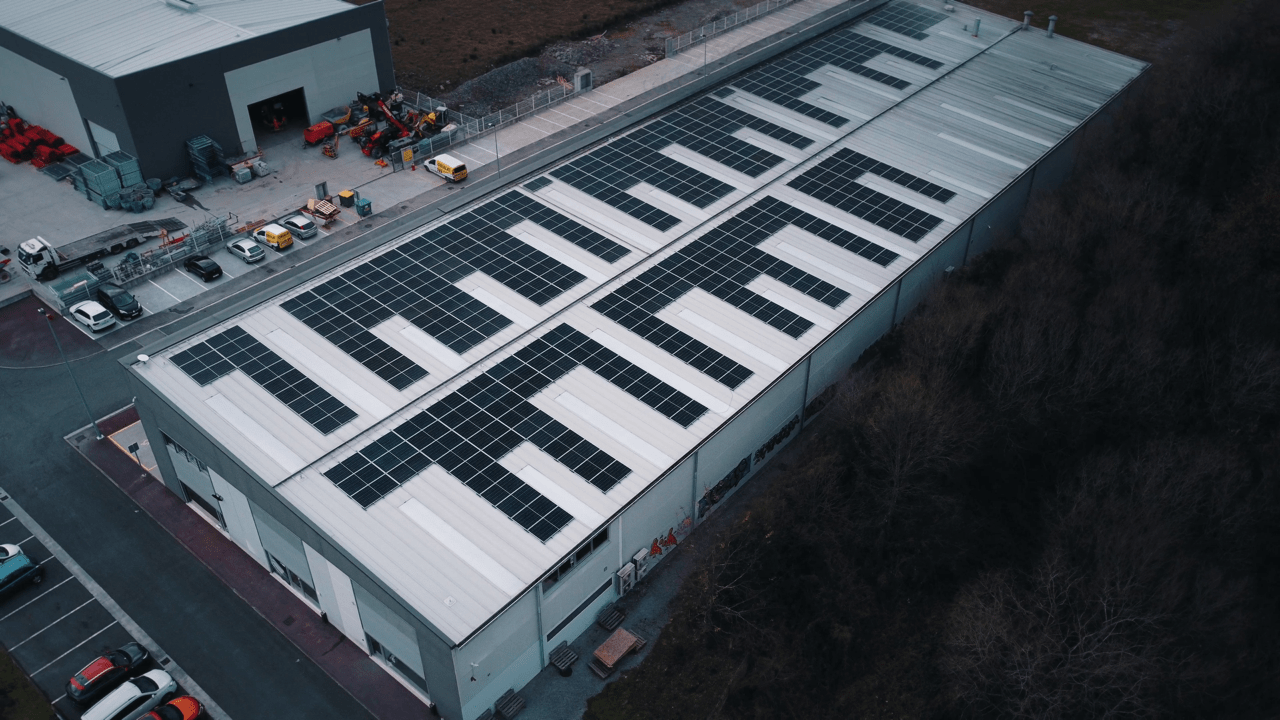

"We've been operating for more than 20 years, but the thing is that we try to improve every day", Jean-Marie explains. "Several years years ago we installed solar panels on the roof and since day one we've been recycling everything, way before it was mandatory." You can tell by the tone of his voice that these are people who care about skateboarding, their community and the environment.

Being from this part of the world, it is part and parcel being involved in the rich traditions of local communties in the north of Spain. They are known for being tight-knit and working together through both difficult and good times. With this in mind, HLC aims to keep the business as local as possible.

"We are trying to keep the jobs in Basque country, as we can do everything here in our factory instead of doing it abroad. So we try to maintain a local workforce here in Europe. That means we have a local impact, since all the workers are from the villages and cities around here. Everybody lives next door".

The Concept

All forms of progress or improvment start with a simple idea. The Section C.B.N. project began by aksing the question, "how can we make our skateboards better...for us and for the planet?"

“Two years ago when Element came to see us at HLC, saying they were trying to develop a more ecologically-responsible board, we've been working together on different varnishes, inks, glues etc. to see what we could do to make this happen" explains Jean-Marie. To determine what components of the skateboard needed to be modified or even eliminated, some serious research had tio be done. Enter the good folks at Air coop.

The Science

With the need for independent expertise when it came to the strategy that Element would take to tackling this project, we contacted Air coop. They are an ambitious cooperative of entrepreneurs and environmental experts based in Annecy, France. Their team came into the project with a great reputation for helping some of the leading brands and business in the sports and outdoor industries with reducing their impact on the planet.

Air coop embarked on a thourough process of conducting a lifecycle analysis (LCA) of our traditionally made Element skateboard decks. An LCA is a science-based method of studying the environmental impact of a product at every stage of its life of use. This was the cruicial step of the project that informed us on how to systematically improve the manufacturing process.

The Process

When the initial findings came back from the Air coop team, their data gave us and HLC the information needed on what parts of the production needed to be evolved or eliminated based on each component's contribution to climate change. For context, they found that the components of a skate deck alone account for 47% of the product's impact on climate change. With that in mind, the development recipie for the board was created. Based on the findings, a mixture of water-based, glues and water-based varnish along with single color graphics, natural wood veneers and a process aided by solar would all contribute to the reduced impact of the board.

A further LCA study was carried out on what is now the Section C.B.N. and through Air coop's work and research, it has been determined that the Section C.B.N as 43% less impact on climate change compared to our traditional decks. Furthermore, with HLC being based in Europe, they must adhere to the strict EU Watse Management Law that sets out a framwork of how waste product must be disposed of and/or recycled, making it a cleaner process than other regions in the world.

The Result

When asked "why should skatboarders give a shit about the planet?", Jean-Marie responded without hesitation and a cheeky smirk — "Because we all live on it". An answer that embodies the spirit of this project.

While this is one skateboard and a first step, the result is a board that skates just as well as our boards that have been trusted by skaters around the world for decades. Having been put through its paces by our pro team, The Section C.B.N. shows that there is no need to sacrifice quality while focusing on the pursuit of change. By combining all of the components of the board and the production process (you can find them here), a 43% reduction in climate impact from a traditional board is a model that can be used for the future.

The Next Step

With these manufacturing practices in place with our partners at HLC, the goal is to not only filter them throughout the Element skateboard range, but also to make this process available to all from 2025. That means Element and HLC invite anyone else who aims to make their boards this way can do so.

Because as Jean-Marie poignantly said ,"if you ask someone, hey what do you prefer? You want a deck that pollutes or a more sustainable deck? Everybody's going to choose the less polluting deck if they have the option."

As Elemnt takes this first, crucial step to make our skateboards in a more responsonsible way, we want to say thank you for your interest in taking the step with us.

Future = Nature.

FAQ's

How is the 43% calculated?

It is a combined calculation that has been ascertained through the conducting of an independent LCA study that you can read here.

Why is the Section C.B.N. only available in certain regions?

Working with the Europe-based HLC factory and aiming to reduce the carbon footprint of the board during its introduction, it was determined that keeping the initial run of boards in Europe a small run in Japan is best until the manufacturing processes are available in other regions.

Will other Element decks be produced in this way?

This is indeed the goal. Aditionally it is the goal to have this technology and manufacturing process available to everyone from 2025.

Where can I buy the Element CBN Board?

You can find the Section C.B.N. in our online store and at one of our retail partners. Find them here.

Is there is difference in the performance compared to other Element decks?

Through a comparative analysis of the new varnish, natural veneeers and water-based glue at the factory and feedback from our team riders, the Section C.B.N. skates the same as our traditionallly made decks. Try it for yourself!